What design sees be what construction gains

BIM (Building Information Modeling) refers to the technology and management methods that apply 3D and 4D information technology throughout the entire or a certain stage of planning, design, construction, and operation, to carry out system design, collaborative construction, virtual construction, construction quantity calculation, cost management, and facility operation.

The application of BIM information technology can eliminate various design hazards that may lead to project delays and cost waste. By utilizing the powerful data and technical support capabilities of the BIM technology platform, the level of refined management throughout the project process can be improved, thereby significantly enhancing project efficiency.

Since its proposal in 2002, it has been widely recognized by the industry worldwide and is hailed as a revolutionary force in the transformation of the construction industry.

Advocate for pre design to avoid post improvement

3P is a team work approach that incorporates lean principles and tools to design quality products and processes.

According to incomplete statistics, over 90% of enterprises do not fully consider factors such as overall layout, production line design, logistics distribution, and process control during the construction of new factories, resulting in low equipment utilization, production capacity, and operational efficiency after the new factories are put into operation. And the waste inherent in these designs will require a lot of time and manpower to improve and perfect in subsequent factory operations.

More and more enterprises realize the importance of lean principles in plant design and new construction. By introducing lean principles in design and construction, enterprises can establish industry-leading lean factories with first-class performance and sound management.

Independently developed APS, MES, and WMS, integrating decentralized information management modules into SMIMS to form lean logistics

Independently designed automated storage and retrieval system, including vertical storage and WMS management system, not only for storage, but also for a wide range of tasks such as production logistics center.

The large warehouse system is extremely flexible in length, width, height and sheet specifications, providing a large space for plate, finished products and residual skeleton. Seamless connection with SMIMS, combined with flexible sheet metal processing unit and automatic loading and unloading mechanism, completes plate transportation, loading, temporary storage of semi-finished products and waste storage, greatly reducing labor intensity, improving production efficiency.

Flexibly utilize tools and ideas such as lean logistics, lean production, IE, value stream, process reengineering, logistics integration, packaging standardization and logistics operation balance, following the development principle of "on the big, starting from the small" and the principle of big logistics and small production, identify the entry points for improving enterprise logistics and take measures such as readjusting factory layout, enhancing logistics management capabilities and introducing logistics automation facilities to reduce production anomalies, improve effective factory output and unit area output, reduce inventory, reduce logistics personnel, cultivate a professional logistics management team and enhance the core competitiveness of enterprise development.

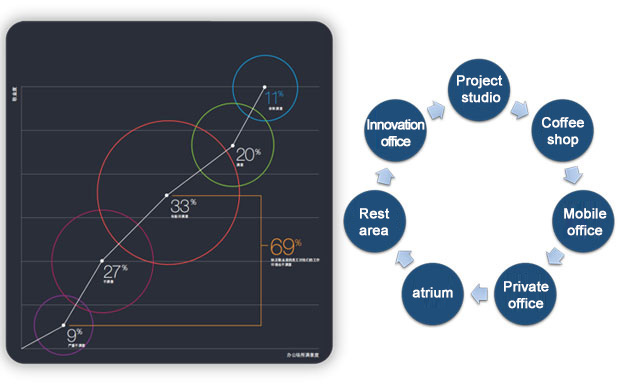

Workplace satisfaction + engagement

This survey conducted by global research firm IPS0S commissioned by Steulcso on 10500 employees found a strong correlation between employee satisfaction with their work environment and their level of dedication. These employees with the highest level of dedication are often the most satisfied with the office environment.

Increase employee satisfaction

Improve team creativity

We have comprehensive manufacturing capabilities, professional lean planning and implementation capabilities

We have the ability to respond quickly and efficiently

We provide one-stop service throughout the entire process

Process automation equipment, digital management system; Apply both soft and hard techniques, not only to give them fish but also to teach them how to fish

Contact us

0511-86288862

wangll@sz-shinetek.com

︿